Cage-Deep Groove Ball Bearings

Cage can be made by different material. Different cages determine the applicability of bearings. can be divided according to cage material:

Pressed Steel Cage

Most pressed steel cages are made of a cold (hot) strip of low carbon, such as 10# steel. Cages made of these materials have high strength and can reduce friction abrasion through surface treatment, and internal stress caused by pressing procedure.

Pressed steel cages are mostly used for medium and small bearings.

Pressed steel cages could also be made of brass.

Machined Solid Cage

According to the materials of cages, machined solid cages mainly include steel cages and brass cages. Aluminum ZL102, powder metallurgy or phenolic compress tube are also used in some applications.

Steel Cages

The mechanical strength of machined steel cages is superior to that of pressed steel cages. Steel cages should be surface treated to improve the capacity of antifriction and abrasion resistance.

Machined solid steel cages are usually used for larger size bearings, or in the application unsuitable for brass cages, e.g. the application that brass is naturally fractured due to chemical reaction.

The highest operating temperature for machined solid steel cages is 300℃, and usually isn't influenced by mineral oil or synthetic lubricant and organic solvent for cleaning.

Brass Cages

Machined solid brass cages are usually used for medium and small size bearings. Brass cages aren't usually affected by bearing lubrication, and could be cleaned by normal organic solvent.

Brass cages are not suitable for working application with the temperature over 250℃.

Injection Mold Cages

Most injection mold cages are made of staple glass fiber reinforced nylon 66. These materials have good intensity, flexibility and gliding, and can keep working for some time under the situation of oil starvation.

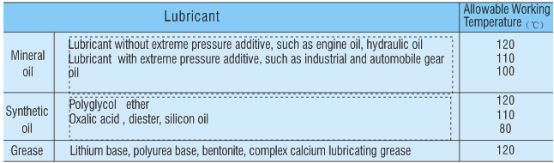

When adopting injection mold cages made of reinforced nylon 66, the influences of allowed working temperature (Table 1) and lubricants corrosion should be noticed. If bearings work under allowable temperature, the performance of nylon cages isn't influenced, and if exceeding this temperature, the material will be aging.

Because nylon will lose flexibility at low temperature, nylon cages are not fit for bearings continuously working under the temperature -40℃.

Under the vacuum conditions, nylon will become crisp due to dehydration, so nylon cages should not be adopted.

Table 1