LYC methodically maintains their quality assurance system, in addition to their advanced inspection & analysis facilities. LYC’s quality controls are traced at source through the metallurgical and chemical composition, mechanical properties ,to production processing into turning ,heat treatment ,grinding and assembly. The process flow is well supervised in order to ensure that their final products’ maintain quality specifications as demanded by their customers.

Testing

Wind bearing test

Yaw bearing test

Gear box bearing test

Main bearing test

Pitch bearing test

General bearing test

Bearing test lab

Hub bearing test

Fatigue life test

CT Bearing Test

Railway bearing test

Comprehensive performance test

Anti water test

Fatigue life test

Dust proof test

Inspection

Raw matreial inspection

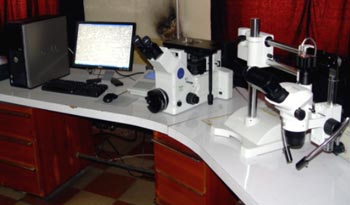

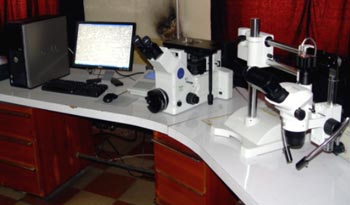

Metallurgical microscope analysis system

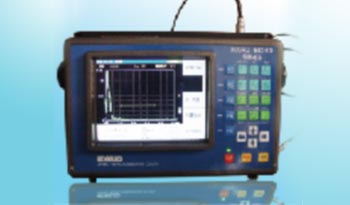

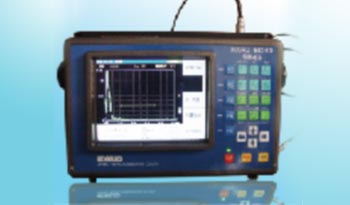

Phased array detector

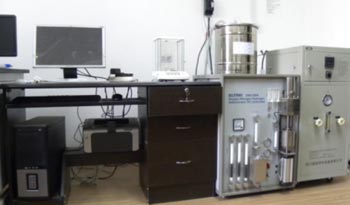

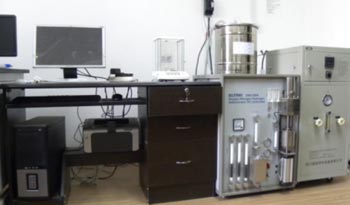

Oxygen and nitrogen hydrogen analyzer

Handheld fluorescence spectrometer

In process inspection

Surface hardness depth tester

Impact testing machine

universal tester

X-ray stress tester

Dimensional inspection

Length measuring instrument

Roundness Meter

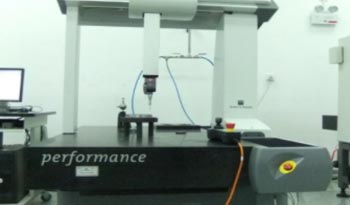

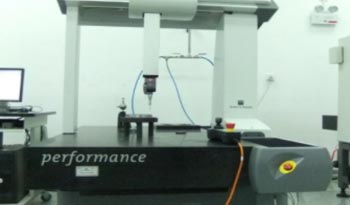

Trilinear coordinates measuring instrument

Hommel roundness instrument